Design obstacles

When designing dental implants, the mechanical analysis often proves to be difficult. Geometries are complex, and the internal mechanics of the implant-abutment connections are too complicated to analyze by simple engineering estimates or reasoning.

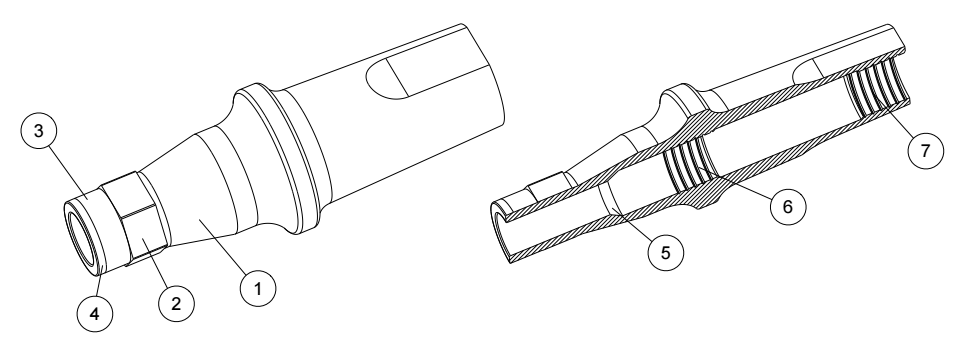

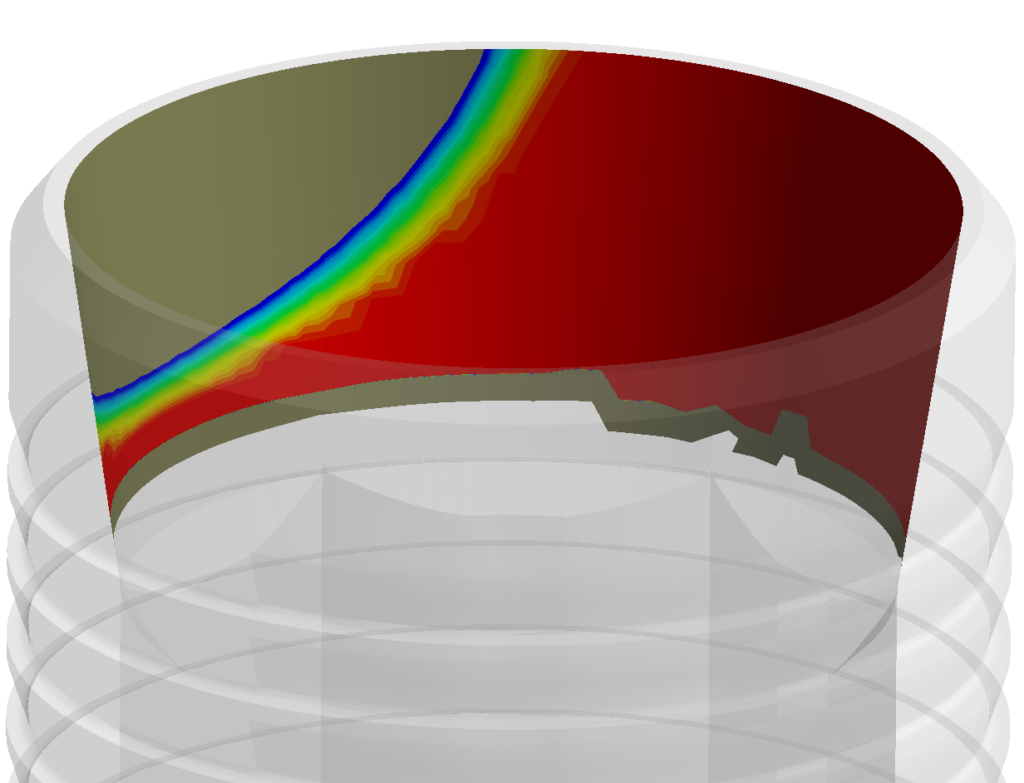

For those reasons, new designs often closely replicate existing solutions, only changing or updating minor things. However, in case of dental implant design, the devil is in the details. Even small changes in design parameters can make or break a design feature. A conical connection between abutment and implant is a good example of this. If the design is done right, the sealing pressure will increase with increased external loading. But often this design goal fails, and in consequence bacteria may enter the implant.

In case of more complete redesigns, the feedback-loop from design iteration to performance test can take months. Real insight in performance requires producing and fatigue-testing prototypes. This in turn makes it very difficult to optimize design parameters, and risky to pursue less conventional designs.

Why not drive your design by simulation?

The reasons for driving design choices with FEM simulation are many and good. To be able to test different designs, optimize parameters and check how variation in production tolerances affect product performance are just a few. It can substantially speed up the design process and create better and cheaper products. However, it requires a precise FEM model, as even small inaccuracies can drive a design in the wrong direction. Simulation models and choices must therefore be based on an existing and proven know-how.