Table of Contents

Finite Element Analysis provides versatile and powerful simulation-based analysis, that have many potential uses in the development of dental implant systems. However, using it requires specialized knowledge and software. Wrong decisions leads to misleading results, typically without warning.

What is Finite Element Analysis?

The Finite Element Method (FEM) is a simulation method, that makes it possible to solve and analyze engineering problems with high mechanical and geometrical complexity.

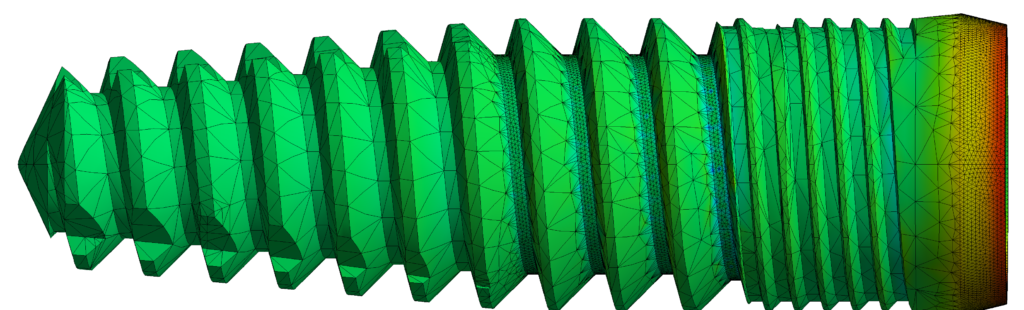

FEM works by dividing the geometry into small separate elements, using what is called a computational mesh. For each element, it is possible to formulate mathematical equations to calculate local stresses, strains, deformation etc. The mesh collects and link all the separate elements into a big interacting network of mathematical equations. For simulating a dental implant, hundreds of thousands of elements are necessary, generating millions of equations. Fortunately, with recent advances in computational power, these can be rapidly solved.

Using FEM for dental implants

The Finite Element Method is extremely useful for designing and producing dental implant systems. It can reduce the number of physical prototypes and experiments, and optimize components in their design phase to develop better products, faster. Please see the Section on FEM Driven Design for additional information.

FEM Analysis can also save time and money when it comes to medical approval. Experiments can be supported by simulated ISO14801 analysis, in order to reduce the number of necessary tests. Important worst-case component configurations can be safely identified. In turn, product approval can be achieved faster and with more confidence. More information can be found in the Section on Simulated ISO14801 tests.

The cases mentioned above are only a few examples of situations, where FEM analysis is useful in the development of dental implants. Take a look at the different Analysis Types we can deliver and our Articles-Section for White Papers and Showcases.

Why not do it yourself?

It is very easy to create a wrong FEM model, as well as extract misleading results from an accurate model. Usually without any warning. The finite element method circumvents certain restrictions on the mathematics governing the laws of mechanics. This is done in a very clever and useful way, and it is one of the key elements that makes FEM so powerful. But with great power comes great responsibility, and you can only break rules if you know exactly what you are doing. Specialist knowledge is paramount in FEM analysis.

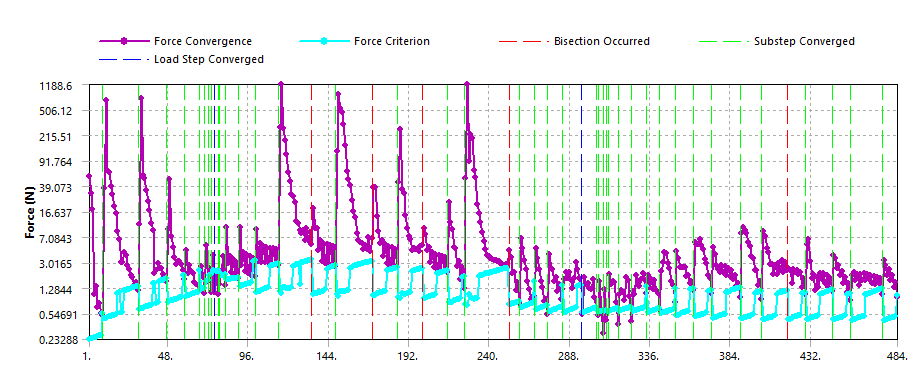

A typical mistake is that engineers discard important mechanical behavior or components. Simply because they are difficult to model correctly, and require a lot of computational power. Frictional interfaces in conical connections and pre-tension are examples of often disregarded important elements. Including all the important mechanics creates a highly non-linear model, which may be difficult to solve. Simplification is a key element in physical modeling, but it must be done on basis of what can rightfully be disregarded. A half-correct model will typically give completely wrong results.

Another culprit is using the wrong software for the job. Several commercially available programs, such as Creo Simulate, Solidworks and Inventor have simplified FEM capability. Unfortunately, they do not model friction, plastic deformation and other important non-linear mechanisms with sufficient precision for implant system analysis. These will output incorrect results without any warning.

What we offer

Det Tekniske Bureau is the leading expert in the field. We have developed our unique and dental implant specific FEM simulation-models and modeling principals throughout years of research, testing and comparison to experiments. Our models are developed not on basis of what was possible, but on basis of what was necessary to get correct results. Download our white paper to read more about the services that we provide.