Which dental implant components configurations are you ISO14801 testing?

Fatigue testing is a necessary, but very time consuming part of getting medical approval for your products. Due to the nature of the tests, they have to run for long uninterrupted periods.

Therefore, it is common practice to select certain ‘worst-case’ component configuration for tests, and then extrapolate the results to a cover a whole family of product components. This is a clever and accepted way to reduce cost and time.

But how do you determine which combinations to test?

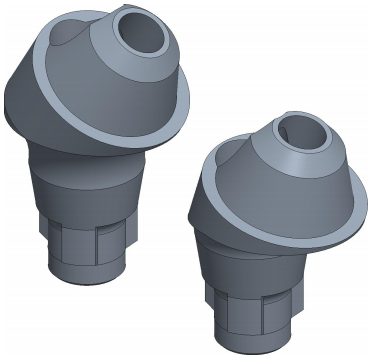

For some designs, this can be determined using simple engineering logic. But in many complicated cases, such as angled abutments and narrow implants, the simple logic doesn’t suffice.

In these cases, Finite Element Analysis (FEA) using precise and verified models can be a great help. FEA can quickly determine which component configurations to test, as well as supply documentation. It can also identify potential design problems prior to initiating months of testing.

Det Tekniske Bureau specializes in aiding clients in dental implant industry fast-track their testing and documentation with supporting FEA. We can help you reduce both your time-to-market and risk. Read More.

#DentalImplants #ISO14801 #21CenturyDentalImplantDevelopment